APV Gasketed Plate Heat Exchangers

APV Gasketed Plate Heat Exchangers

Since the first commercially successful design was introduced by APV’s founder Dr. Richard Seligman in 1923, the plate heat exchanger has become one of the most versatile and cost-effective methods for the indirect heating and cooling of fluids. The basic concept is to run fluids on either side of a thin metal plate so that heat may be transferred between the two fluids.

Since the first commercially successful design was introduced by APV’s founder Dr. Richard Seligman in 1923, the plate heat exchanger has become one of the most versatile and cost-effective methods for the indirect heating and cooling of fluids. The basic concept is to run fluids on either side of a thin metal plate so that heat may be transferred between the two fluids.

Other Details :

- Availability : Available

- MANUFACTURERS : spxflow

- Description

- DOWNLOADS

- Reviews

Description

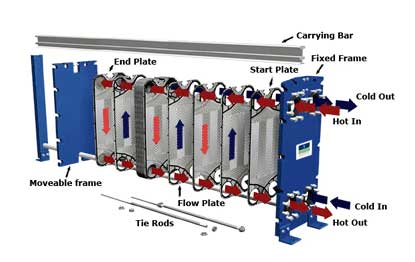

The paraflow is the original plate type heat exchanger designed by APV to provide maximum efficiency and cost effectiveness in handling thermal duties while minimizing maintenance downtime and floor space requirements. THE FRAME The paraflow plate heat exchanger, consists of a stationary head and end support connected by a top carrying bar and bottom guide rail. These form a rigid frame, which supports the plates and moveable follower. In most units, plates are securely compressed between the head and follower by means of tie bars on either side of the exchanger. In a few models, central tightening spindles working against a reinforced end support are used for compression. When Paraflows are opened, the follower moves easily along the top bar with the aid of a bearing-supported roller, to allow full access to each individual plate. With the exception of some sanitary models, which are clad with stainless steel, paraflow frames are fabricated of carbon steel and are finished in chemical resistant epoxy paint. Frame ports accept bushings of stainless steel or alternative metals, which with various types of flanged or sanitary connections, form the inlet and outlet nozzles. By using intermediate connector plates units can be divided into separate sections to accommodate multiple duties within a single frame.