RITEPRO

RITEPRO

SPECIFICATIONS

MODELS: 201, 203, 205, 210, 212, 312, 260, 211

SIZE RANGE: 1" - 60" (25mm - 1500mm)

PRESSURE RATINGS: PN10, ASME 125 lb, ASME 150 lb, PN 16, PN 25, ASME 300 lb, PN40

BODY MATERIALS: ASTM A 126 CLB, ASTM A 395, ASTM A 216 WCB, ASTM A 351 CF8M, Titanium

SEATS: BUNA-N, EPDM, A240 - 304 (Inserted or Integral) ***, PFTE, Viton

SPACERS: PTFE (Standard on 1" - 12" Cast Iron Bodies), A479 - 316

APPLICATIONS: Reduction of Water Hammer

Other Details :

- Availability : Available

- Description

- FEATURES

- SEATS

- THE RITE ADVANTAGES

- SELECTION PROCESS

- DOWNLOAD

- SOFTWARE

- Reviews

Description

STATE OF THE ART CHECK VALVES

Ritepro’s Rite wafer combination swing check valves are flow activated and Rite Sized. Rite inlet ports and disc have been shape optimized to achieve a fully open position at low flow rates (3 ft/s on average). Therefore, the Rite operates exceptionally well in the flow rates typically found in pipelines containing control valves and lines with varying media flows.

Compare the Rite to typical full-sized swing check valves. Due in part to their oversized, heavier discs, these valves only fully open at an average flow rate of 11 ft/s. When activated at a lower flow rate, these valves loose true controllability and do not fully open. A partially open disc creates an obstruction that produces a higher pressure drop and fluttering of the valve disc - disturbing the flow and increasing the chance of water hammer.

Compare the Rite to typical full-sized swing check valves. Due in part to their oversized, heavier discs, these valves only fully open at an average flow rate of 11 ft/s. When activated at a lower flow rate, these valves loose true controllability and do not fully open. A partially open disc creates an obstruction that produces a higher pressure drop and fluttering of the valve disc - disturbing the flow and increasing the chance of water hammer.

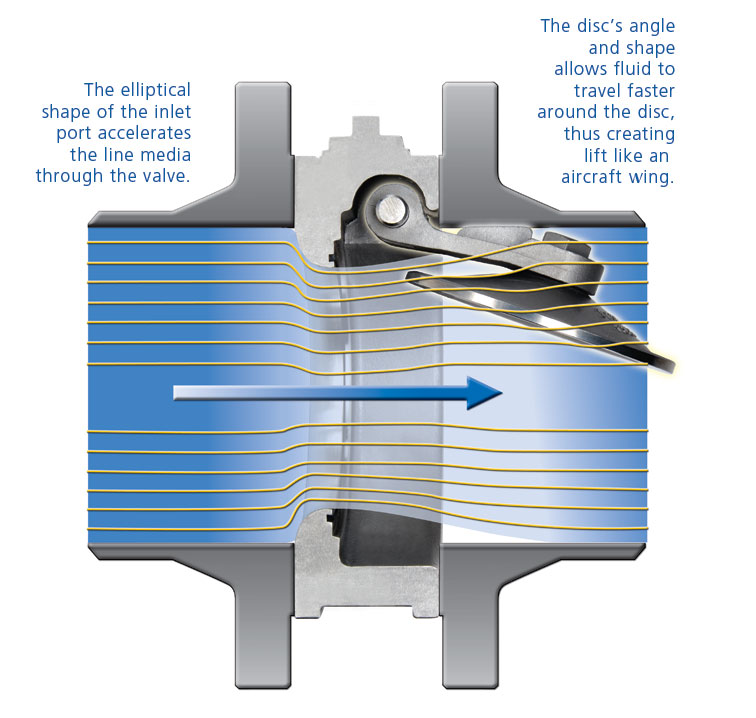

Rite is Rite Sized to eliminate these problems. It has been engineered to accelerate line media through the valve and achieve a virtually unobstructed full opening in low pressure. Rite Sized, combined with the limited movement of internal parts during operation, reduces wear – enhancing the long service life of a Rite valve.

FEATURES

ZERO LEAKAGE

Rite valves, either resilient or metal seated, offer zero leakage in all pressure classifications. Each valve is hydrostatically tested at the factory and shipped with a certificate of compliance to MSS SP61. Ritepro has achieved zero leakage metal-to-metal sealing by a proven, engineered design backed by high quality manufacturing craftsmanship. As the disc closes toward the seat, the increased velocity of the line media and the unique shape of our seat remove all particles from the sealing surfaces.

LOW PRESSURE DROPS

The low pressure drop of the Rite valve was achieved by Ritepro’s many years of research and development in combination with universities and federal research agencies. Several theses and papers were published including minimizing the pressure loss of wafer type swing check valve ASME 79/MA-NE-5. These results – primarily the optimum valve diameter and elliptical inlet shape have been incorporated into the Rite design. Like a venturi, the aerodynamic shape accelerates the line media through the valve with the lowest possible pressure drop. Pressure drops at the full open position are between 0.5 to 0.7 psi for all size valves. Additionally, the disc shape and mass have been optimized to use the pipeline media flow as a lifting force on the disc, thus allowing a full open valve position in low line velocity.

HIGH FLOW CAPACITY

Rite’s valve inlet elliptical shape and optimum diameter, plus its virtually unobstructed opening combine to produce a substantially higher flow capacity (Cv) than other wafer combination swing check valves.

REDUCED WATER HAMMER

An additional focus of Ritepro’s R&D program was linked to water hammer prediction. Findings were applied in the design of the valve to largely reduce or eliminate water hammer by closing the valve at the right moment (before reverse flow occurs). The Rite uses gravity, assisted by an internal spring, to pull the disc toward the closed position on decelerating line media flow. Ritepro has developed proprietary predictive software to select the best solution for your specific application.

SEATS

RITE SEATS

Zero leakage shutoff, even at 0 psi, is achieved through lapped metal seating surfaces. The seat and the disc edges are precisely machined then hand polished for a perfect fit. The disc hinge provides an even force at the disc to seat contact point, ensuring a uniform seal. Controlled tolerances maintain the proper disc to seat alignment. The spring assisted closure tension holds the disc in place when line pressure is removed.

RESILIENT SEATS

A dynamic, O-ring seat is contained in a specially designed body groove. As line pressure is applied, the valve disc uniformly compresses the seat into the groove ensuring a zero leakage seal. The seat is easily replaced, simplifying maintenance.

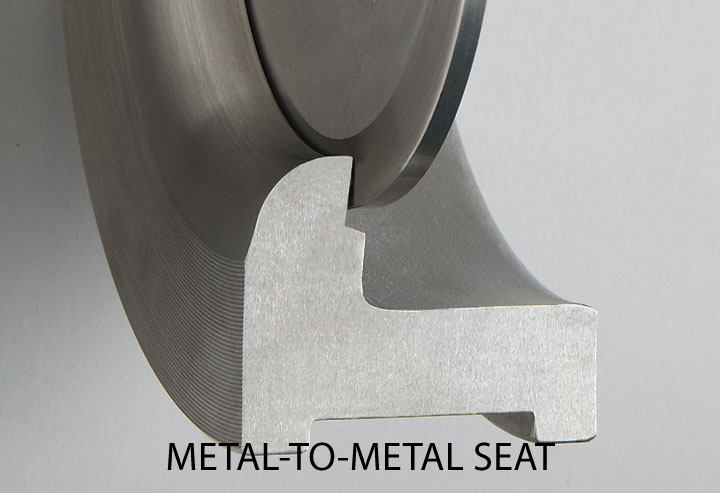

METAL-TO-METAL SEATS

Integral metal seats feature an engineered and precision machined angle that minimizes the metal-to-metal contact point between the disc and seat for a perfect seal. Pressure is applied evenly over the disc, eliminating galling and reducing wear.

METAL SEAT INSERT

Carbon steel and ductile iron bodies have a stainless steel seat inserted into the body seal area, offering the same precision design as the integral metal-to-metal seat. These bodies are also available with a resilient seat insert.

INHERENTLY FIRE SAFE

All Rite valves are inherently fire safe due to the valve design, materials and construction. In the event of a pipeline fire, both resilient seated and metal seated valves provide metal-to-metal contact between the seat and disc and surpass all leak test standards.

THE RITE ADVANTAGES

PUMPING COST SAVINGS

Pumping costs have been often overlooked but are now gaining in importance due to the increasing cost of energy. With Rite’s long service life, its cost is actually insignificant to the end user compared to the energy lost pumping the fluid through the valve. Below is a comparison between different valve styles, assuming all valves are 100% open.

Yearly Energy Costs Comparison At 10 F/S - $0.10/kWh

| VALVE SIZE / INCHES | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 |

| Rite | $42 | $66 | $99 | $174 | $250 | $254 | $635 | $872 | $1113 |

| Tilting Disc | $50 | $66 | $102 | $161 | $250 | $272 | $425 | $606 | $739 |

| Center Guided "Silent" | $115 | $214 | $339 | $608 | $1002 | $1409 | $2541 | $4006 | $3447 |

| Full Size Swing Check | $57 | $66 | $99 | $191 | $250 | $415 | $680 | $1002 | $1347 |

| Dual Door | $218 | $209 | $314 | $441 | $491 | $707 | $979 | $1118 | $1282 |

HORIZONTAL/VERTICAL INSTALLATION

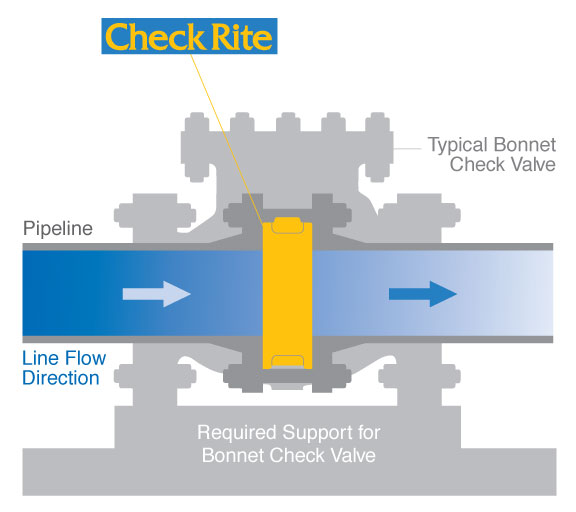

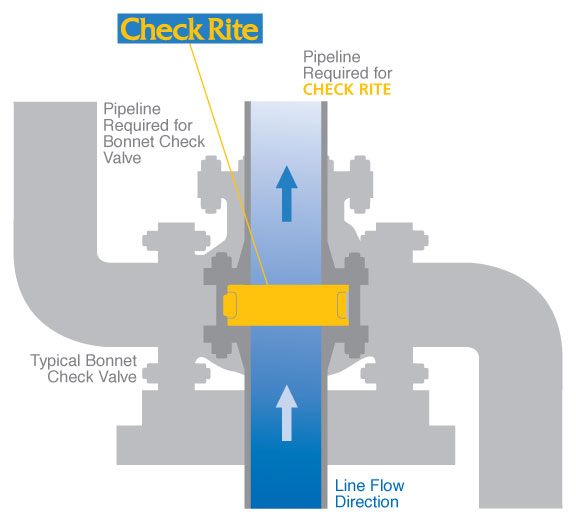

Unlike most conventional check valves, Rite wafer combination swing check valves are ideal for both horizontal and vertical pipeline installation – requiring only a single line for operation. This greatly increases pipeline layout flexibility and significantly reduces costs. In vertical installations, typical swing check valves must have an offset pipe section installed since these valves only function in a horizontal position. See factory for vertical down applications.

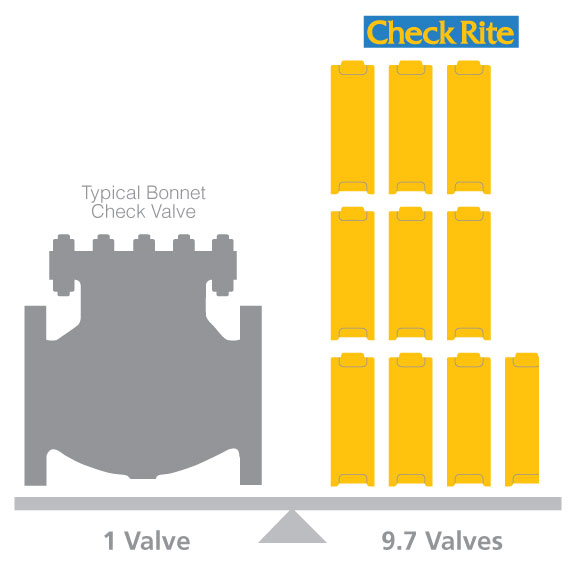

LIGHT WEIGHT & REDUCED SIZE

Installation costs are greatly reduced by Rite’s light weight and minimal space requirements. Their compact design minimizes the distance between faces and are easily installed between all flanges. Rite valves do not require added support to maintain pipeline integrity and need only 30% of the space of typical full size swing check valves.

SELECTION PROCESS

SELECTION PROCESS

Gather Process Information:

- Line Fluid / Pressure / Temperature /

- Flow Rate / Location / Function

Gather Pipe Information:

- Size / Material /

- Flange Rating / Schedule

Select Valve Size - Based on:

- Full open valve at minimum flow

- or Pipe Size

Select Design Standard:

- ASME: 125 / 150 / 300

- API 594: 150 / 300 / 400 / 600 /

- 900 / 1500 / 2500

- PN: 10 / 16 / 25 / 40

Verify Conditions:

- Valve full open at minimum flow

- Max velocity 15 f/sec for Liquid

- Max velocity Mach 0.33 for Gas

- Non-reciprocating service

- No accessories required

- Installed with a minimum of 5 pipe diameters upstream and 3 downstream from a disturbance.

- Not installed on close coupled multiple pump header

Select Model:

If answer is YES to All conditions:

- Select Model 210 (ASME, DIN)

- Models 201 - 205 (API 594)

- or if ULC FM* approved required select 212 (ASME), 312 (DIN) 2" - 12" ONLY

If answer is NO to Any condition:

- Select Model 260 (ASME, DIN)

- Models 201 - 205 (API 594)

- Select Pressure Class and Body, Seat & Spacers Materials, and specific application accessories as required.

ORDERING EXAMPLE

A 6" heavy duty, Class 150 wafer combination swing check valve, carbon steel body with stainless steel inserted seat, stainless steel spacers and an external spring accessory would be written as follows:

06 15 SMZ SA01

DOWNLOAD

Check Valves & Accessories Sales Brochure

Check Valves & Accessories Sales Brochure in English (US)

Check Valves & Accessories Sales Brochure in Portuguese (PR)

Check Valves & Accessories Sales Brochure in Chinese (CH)

Check Valves Sales Flyer

Check Valves Sales Flyer in English (US)